Your Coil Specialists

More than 80% of heating and cooling coils in the HVAC industry don’t make it to old age and need replacing. There are so many reasons why they fail prematurely that we can’t name them all in one newsletter. However, we can review the most egregious ones in commercial and industrial systems.

Coil Construction or Arrangement

Years ago, HVAC coils were constructed of much heavier copper tubes, aluminum fins, and galvanized steel frames. Why? Because the cost of these materials was much less. If you replace coils from 40 or 50 years ago, it would be considered “a tank” in comparison to today’s finned tube coils.

The lighter coil materials used today do not have an extra margin for adverse temperatures or adverse pressure, and a coil’s materials are moving all the time. This expansion and contraction can wear out a lighter duty coil faster than years ago. Also, lighter duty coils have brazed joints that are not nearly as strong as the older coils. Heavier materials produce a better bond between tubes and return bends and between tubes and manifolds.

Coil designs have many different fin patterns. This means that we have the technology to have the air touch more of the fin surface (known as the secondary surface), which creates more heat transfer per square feet. However, in a system that is difficult to clean or maintenance is suspect, these surfaces can collect a lot of dirt and debris and will significantly reduce air flow and overall heat transfer. We’ve seen coils so packed with dirt that they’ve been ripped out of their piping, because the fans are starving for air.

More than other coils, condenser coils are the ones that have this problem most often. If you think about it, condenser coils have no filter on the entering air side and use all outside air. In many installations and environments, this outside air can cause tremendous loading of coil cores. Most air-cooled products have prop fans, and any added pressure can reduce air flow and cause refrigerant systems to have high pressures and eventual compressor failures.

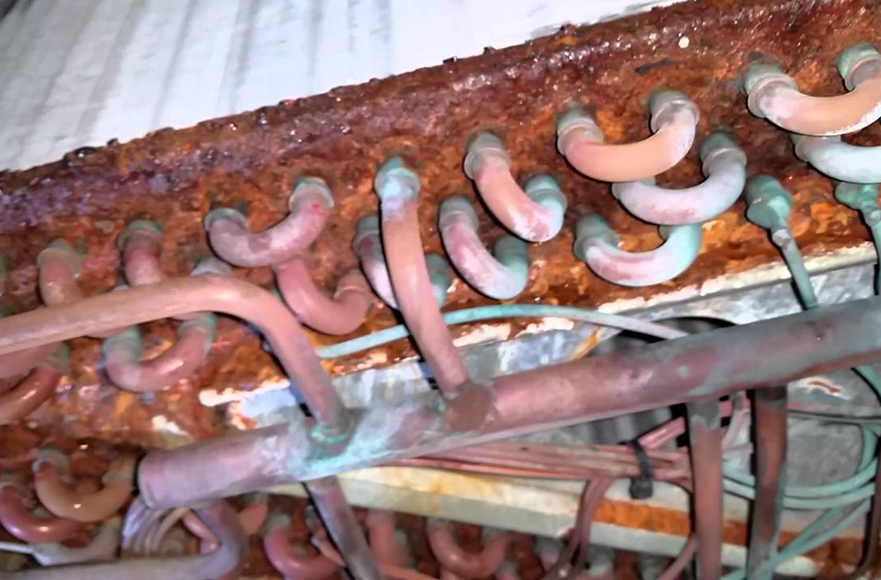

Corrosion

Condenser coils have problems in salt laden environments. This condition is technically called “electrolytic corrosion”, and it simply means salt is present where two dissimilar metals are in contact with each other (one being passive and the other negative). The salt starts to eat away at the aluminum fins and begins to lose secondary heat transfer, as well as losing contact between the tube and the fin. Initially, it will look like a chalky white substance forming a ring around the tube. This tells you corrosion is taking place. If left to continue, the coil airside fills with this white scale and reduces air flow.

There is also water and steam side corrosion that normally happens over time through treatment. During treatment, corrosive agents can build to a point that they begin to cause tube and return bend leaks. The big 3 are 1)oxygen, 2) carbon dioxides, and 3) ammonia. We have seen many systems leak free for a decade and in the next 3 years have multiple leaks and need to have coils replaced. These leaks normally are on the bottom of the tube diameter and look like ratty irregular holes. This is an indication that the corrosive agent is now at a volume that will destroy the copper.

Coil Freeze Event

Any water or steam coil could freeze if the coil receives freezing air to its entering air side and the fluid inside the coil stops flowing. We have done tests, and with 10-degree F air and water sitting in a tube, the coil will burst in a matter of minutes with moderate air flow across the coil.

- What happens during a freeze event? The inside of the coil is having its internal pressure raised to a point that the tube and or return bend can no longer hold the pressure. It’s why you see a bloating of the tube or bend and then a crack in the middle of the bloated area.

- Why do return bends fracture more than tubes? It’s because the wall of the bend is slightly thinner than the tube wall. Therefore, it’s prone to a fracture faster than the coil tube.

Chilled water coils can freeze because water is still laying in the coil. Many coil designs do not drain 100%, because tube circuits are below the lowest connection of the drain connection.

Steam heating coil hardware (valves, vacuum breakers, and traps) may not be sized properly, or they are not in the correct position. Therefore, condensate can’t be removed as quickly as it’s formed if there’s not a positive pressure at the inlet to the trap.

Southwest Coil exclusively represents USA Coil & Air in the Southwestern Region. In our 40+ years, we have seen it all and can help you design new coils to withstand your special problems. We solve problems – not create new ones. We can replace all coils regardless of their age, make, or construction and have expedited shipments for those emergency situations. We are your one-stop source for replacement and special application coils. Take advantage of our decades of knowledge and experience.