Why Large Tube Diameters Work Better With Steam Coil Heating

America has been using steam heating for 120 years. Much of today’s technology gains have been based on problem solving of inefficient systems and providing coil heat exchangers that improve both capacity and longevity. I have personally seen many systems that never had a chance to work properly – due to use of an improper coil for the application or an installation that had incorrect steam specialties feeding the steam and the removal of condensate.

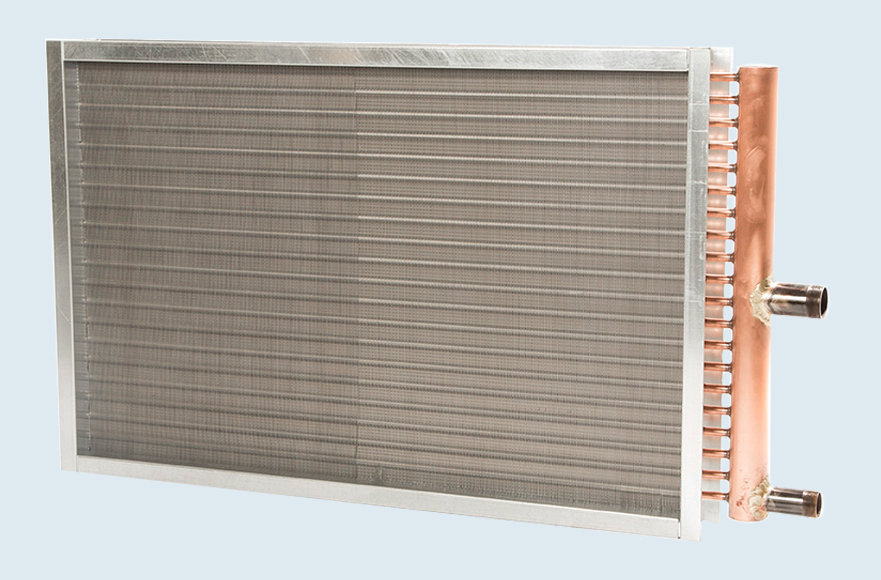

Let’s look at how a steam coil operates. Steam is inserted into a header (sometimes known as a manifold) and then sent through tubes. Most coils are same end connected, so the steam being sent from the connection end will be returned as condensate to that same end. About 90% of all coils are piped this way because 1) it costs much less for piping and 2) the entire coil, including manifolds, takes up considerably less space in the overall length of the coil.

Most preheat and reheat coils today are under 15 PSIG steam pressure. This is known as “low pressure” and is used because high-pressure steam wears out coils faster. Usually there is a pressure reducer in the system to supply this low-pressure steam.

Since the steam goes down to the other end of the coil and condensate returns in the opposite direction, a coil type referred to as a “steam distributing” coil is used. Some manufacturers call it “non-freeze”, but that would be a misnomer, because any steam coil with condensate held in the coil will eventually create a freeze event if below freezing air continues to be delivered.

The $64,000 question is, “What causes condensate to be held inside a coil during operation”? Steam accessories must keep the coil in a “positive flow condition” at all times. To do this, the trap located on the condensate exit side of the coil has to be at a positive pressure. The trap must remove condensate as quickly as it’s formed. What causes “negative pressure”? Negative pressure is usually created by the steam valve modulating during intermediate load days. If a coil is sized for 15-degree air at its lowest temperature and it’s a 28-degree day, the modulating valve will close to ensure the leaving air temperature is the same. Less steam equals less capacity and less temperature rise.

During this process, the inside of the coil may go into negative pressure. Usually a vacuum breaker can help to maintain zero pressure, but it’s not guaranteed. Many times, traps and lines are not properly sized or not in the correct position and will continue to cause negative pressure at the inlet to the trap. You can also have lifting condensate after the trap that creates negative pressure. Simply put, if a system is negative, condensate in the coil will not flow properly. Lack of removal of condensate can create hot and cold spots on leaving air face of the coil which cause inefficiency with capacity, freeze events and corrosion over time.

One way to assist with the steam and condensate flow is increasing the size of the outside diameter of the tubes. Remember that a steam distributing coil has a set of inner tubes and outer tubes. When looking at a coil, you can only see the outer tube but there is an inner tube inside the one you see. The inner tube is the “steam distributing tube” and the outer tube is the “condensate tube”. The inner tube has holes along the length of the tube. This allows for steam that becomes condensate to be pushed out into the condensate tube (outer tube). The higher the volume of both the inner and the outer tubes, the less restriction to the flow and a greater chance of having even steam down to the far end and uniform condensate collection and removal returning to the connection end.

One way to assist with the steam and condensate flow is increasing the size of the outside diameter of the tubes. Remember that a steam distributing coil has a set of inner tubes and outer tubes. When looking at a coil, you can only see the outer tube but there is an inner tube inside the one you see. The inner tube is the “steam distributing tube” and the outer tube is the “condensate tube”. The inner tube has holes along the length of the tube. This allows for steam that becomes condensate to be pushed out into the condensate tube (outer tube). The higher the volume of both the inner and the outer tubes, the less restriction to the flow and a greater chance of having even steam down to the far end and uniform condensate collection and removal returning to the connection end.

Steam systems with low pressure, same end connections, and longer tube lengths need all the benefits you can provide to work properly during every day it’s in operation. That benefit can be achieved by specifying the 1” OD type coil design.

Southwest Coil exclusively represents USA Coil & Air in the Southwest Region. We have been manufacturing all types of single tube and double tube steam heating coils for decades. We are the experts! If you have problems with freeze events, irregular heating, and corrosion; we can help you discover the cause of the problem and supply you with a coil arrangement and construction that will create better efficiency and longevity. We have standard lead times, as well as 3 different expedited shipments for emergency situations.