Test Your Condenser Coil Knowledge

Condenser coils have a high number of fins per inch due to which of the factors listed below?

a. Helps distribute the air across the tubes

b. Drastically improves heat transfer

c. Reduces cost

d. Reduces air resistance

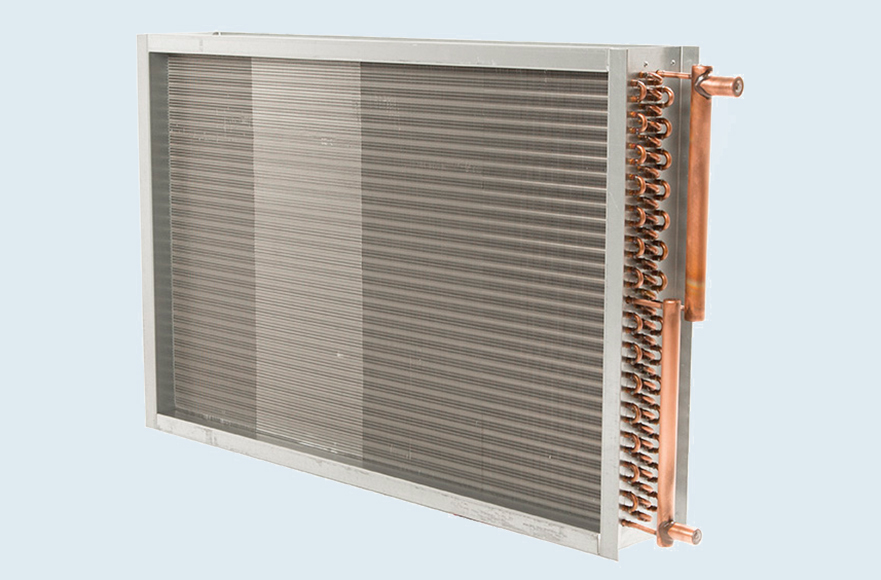

Fins on any coil assist in the distribution of air across the tubes, so adding more fins doesn’t make much of a difference. The answer is (b) Drastically improves heat transfer. Because a condenser coil is a dry coil, adding fins significantly assists with the overall BTUH efficiency. There is a huge difference in capacity between a 3 row 10-inch fin per inch coil and a 3 row 18-inch fin per inch coil.

Which of the following performance characteristics influences condenser coil performance the most?

a. Air flow quantity

b. Refrigerant type

c. Condenser fan location

d. Fan/motor voltage

Neither the refrigerant type, location of the condenser fan, nor the electric voltage of the condenser fan/motor makes much difference in condenser coil performance. The answer is (a) Air flow quantity. Condenser coil capacity is all about air flow. When the air flow is reduced, then the BTUH capacity falls dramatically.

When the term “TD” is mentioned regarding a condenser coil, what’s it referring to?

a. Difference between evaporator and condensing temperature

b. Difference between design evaporator temperature and actual performing evaporator temperature

c. Difference between design ambient air and condensing temperature

d. Condenser system scores a touchdown

It certainly isn’t a touchdown (TD), and it also has nothing to do with the evaporator. The answer is (c) Difference between design ambient air and condensing temperature. This relates to the maximum design entering air temperature (known as ambient air temperature) and the design condensing temperature. There is 30 degrees between the two, so the “TD” would be 30.

When you look in the fin surface and see a white powdery circle around the tubes, what does this indicate?

a. Dirt and debris have migrated into the core of the coil

b. Cleaning solution has not been properly removed

c. Electrolytic corrosion has begun

d. None of the above

While dirt, debris, and a cleaning solution, all migrate over the coil core; none of these is exhibited as a ring around the tubes. The answer is (c) Electrolytic corrosion has started. When the salt laden atmosphere creates corrosion, it’s technically known as electrolytic corrosion. This is nothing more than the salt attacking dissimilar metals in contact with one another. The dissimilar metals are copper tubes and aluminum fins. Dissimilar meaning one is passive and one is active. The aluminum is attacked directly at the point of contact, and it’s why you can visually see the white ring around the tubes. The white ring is the breakdown of the fin where it contacts the copper tube. This reduction bond between the primary and secondary surfaces can reduce the capacity of a condenser by up to 50%. Heat transfer is affected, and as the white powder builds, the coil air resistance builds creating a significant reduction in air flow and further reduced capacity.

What causes the condenser coil to begin developing leaks in or near intermediate or connection end tube sheets?

a. Piping configuration may need to be reviewed

b. Unit has developed excess vibration

c. Piping weight on the connection and headers of the coil is adverse

d. There is a coil manufacturing defect

Very rarely is the cause a manufacturing defect. Coil manufacturers understand that building condenser coils with quality control in these areas is of paramount importance. Also, rarely is it piping weight on the connection and headers or the piping configuration by itself. Therefore, the answer is (b) Unit has developed excess vibration. There are many unit designs that radiate adverse vibration throughout the condenser coils. Condenser fans, motors, and compressors can be mounted too close to the condenser coils, and over time, the vibration creates these failures. The unit design may also have inadequate structural members to alleviate the radiation of vibration to the condenser coils. Over the past few decades, the HVAC industry has moved manufacturers to create packages that have less overall weight for mounting and shipping considerations and to also lower first cost price.

Systems also change over a long period of time. A new system may be close to radiating excess vibration, but poor maintenance or just older operating compressors and fan/motors takes this vibration and makes it excessive. This can be confirmed when a condenser coil has operated leak free for 10 years and then suddenly, within a two-year period, the condenser coil has multiple leaks at the tube sheets. The system has changed, and the vibration is now excessive.

Historical Quote

“You have the freedom of choice – but never the freedom from consequences!”

Southwest Coil’s Monthly – “We got a beef!”

Southwest Coil takes a very proactive approach when it comes to pointing out the specific reason(s) your coil is failing. We want to help, as well as inform, our customers – not just replace a problem with a difference problem. Unfortunately, many customers don’t heed our warnings and frequently have failures with the new coils. As the old cliché says, “you can lead a horse to water, but you can’t make them drink”.

And one more thing…

Southwest Coil is the exclusive representative for USA Coil & Air in our territory. Together our expertise in evaluating and solving problems related to coil failures is well established over our five decades in the replacement coil industry. Our sales engineers will work one-on-one with you to evaluate and determine the correct solution to your problems. Together, we create results that save you time and money!