You Have Questions… We Have Answers

Each month we publish questions we receive about coils and air handler systems and applications. There are many installations that have inherent problems that can cause lack of performance and/or system downtime. The following are some of the problems that affect many of our customers.

We service many fan coil unit systems in apartments and condominiums in the Denver metropolitan area. We continually see air throw problems which produce hot and cold spots within the conditioned area. What can we do about this type of problem?

Brian – Service Contractor – Englewood, Colorado

Throughout the USA, air throw problems exist in about 75% of all fan coil unit living space installations. It indicates a rampant problem. The fan coil unit installation is the least expensive way to provide heat and air conditioning to a space. It provides distribution of piping but very little, if any, distribution of the air side ductwork. This reduces the air distribution evenly and effectively within a space. Without ductwork, the unit has minimal power consumption (HP) to deliver air flow per ton. Horsepower is increased when more resistance is added to the return and supply side air distribution, so most have little to no ductwork.

There are units located in positions whereby the air throw from the supply grille is not adequate to heat or cool those areas that are a long distance from the unit discharge. The problem is exasperated further when these distant areas are “high load” areas, such as windows and southerly exposures.

The system is also stuck with a water distribution system that has fixed water volume and temperatures. Some systems may be providing less water volume and temperatures than what was originally specified – creating an even bigger cooling problem. Coils can become dirt laden, and the fan coil units de-rated in capacity due to the further reduction in air flow.

The answer is usually a unit change that will enhance capacity and significantly improve air throw. Many of today’s fabricated units have much better air distribution than the ones installed decades ago. The problem is that the committees and/or owners may not be willing to pay the money necessary to achieve the increased performance.

We have many air conditioning units located near the Pacific Ocean. Can you give us a good guesstimate of how long a standard aluminum fin coil will last in this environment?

Kim – Service Contractor – Escondido, CA

Salt laden atmospheres will destroy aluminum fins in a short period of time. The degree of salt and the amount of cleaning have a lot to do with the overall lifespan of the units. Let’s look at both.

The degree of salt is based on the proximity of the unit to the salt laden atmosphere. Predominant wind direction can also play a part. We’ve seen units located on the beach that only lasted 3 years and had to be replaced, while units 3 blocks from the beach lasted 6 years.

In salt laden atmospheres, timely cleaning of the coils is extremely important. Today’s condenser coils have a great number of fins per inch, and the fins themselves are thin and flimsy. Based on the severity of the salt involved, cleaning schedules must be increased as well. Salt corrosion destroys the performance of the coils. It eats away at the tube, which is the fins contact point for heat transfer. If your cleaning does not get to the root of the problem, cleaning becomes an exercise in futility. Many coils look clean when you walk up to the coil. However, you can see the white circle near each tube which tells you that erosion of the fin has started.

We’ve always sold new condenser coils with a tried and proven baked-on coating, which will last 3 times as long in a salt atmosphere. Through decades of experience, we’ve found it’s the only way to go. Be cautious, as many in our industry will want to sell you spray-on coatings, which are only 5% as effective as the baked-on coating. In this case, you truly get what you pay for!

We see older units with very rusted out coil sections, and the worst are the drain pans and the coil casings integral to the coils. Is there a way to reduce the rust problem in our new specified units?

Lanny – Consulting Engineer – White Plains, NY

We see older units with very rusted out coil sections, and the worst are the drain pans and the coil casings integral to the coils. Is there a way to reduce the rust problem in our new specified units?

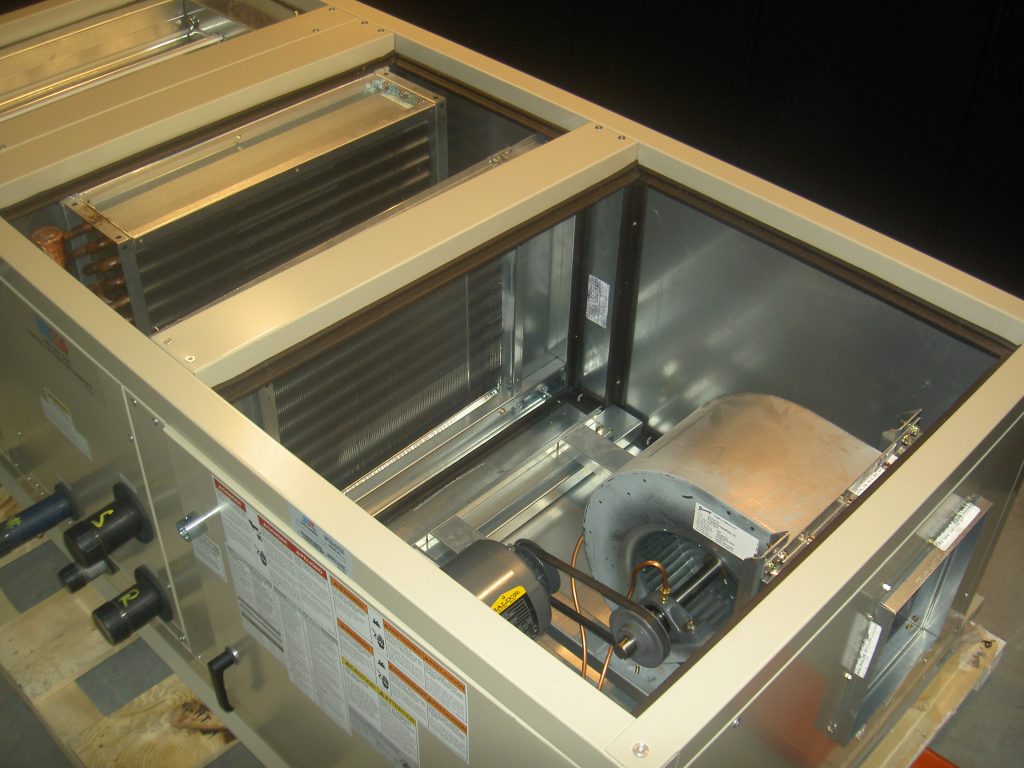

Most of today’s large central station units include stainless steel drain pans. Personally, I would specify that any cooling section in a fan coil unit have a stainless-steel drain pan – whether it’s a commercial belt drive unit or a packaged unit. It just makes good sense. In larger systems, I would also specify stainless steel coil casings and safe offs and baffles to be the same. Essentially, anywhere that dehumidified water hits the metal. I would also specify stainless steel liners (inner wall) since most units are now double wall construction. To keep costs down, the coil section only can be stainless steel inner wall.

Southwest Coil exclusively represents USA Coil & Air in the Southwest Region. We have been building replacement coils and air handlers for 4+ decades. We are the leaders in the HVAC industry. Our unit selections and designs are all flexible and can be built to meet your exact application. We invite you to take advantage of our decades of knowledge, experience, and professional sales staff.