Why Do Coils Need to be Replaced Before the Unit Needs to be Replaced?

This question is a complex question with many answers. However, all of them fit one of three categories. These categories are, 1) inadequate coil design and/or construction, 2) adverse temperature/pressure and corrosion, and 3) inadequate maintenance. All these reasons could be avoided if we lived in a ‘perfect” world. Let’s examine each category a little closer.

Inadequate coil design and/or construction

The HVAC industry is very competitive, and cost is the #1 advantage factor. Larger commercial and industrial units are heavy and have a large footprint. The competition forces unitary manufacturers to constantly redesign their packages to obtain the least amount of weight and smallest footprint, as crating and shipping create the lowest cost. Manufacturers also need to be competitive in designer’s selections of roof or pad mounting applications. This competition may mean creating coil designs that are marginal – even for the most standard units. Less weight could mean lighter tube walls, thinner fin surfaces, and lighter weight coil frames. The coils themselves may be mounted very near vibrating equipment (compressors, fans) that can cause wear to the tube surfaces and create multiple leaks.

Microchannel heat exchangers have become a great alternative to finned tube condensers because of the quality performance aspect. The problem is that these designs do not create longevity in HVAC applications. In just a few years, we’ve worked on hundreds of packaged units that have replaced microchannel heat exchangers – sometimes just because the down time with leaks was unacceptable.

Adverse temperature/pressure and corrosion

Not every installation is a shopping mall or clean office application. Many standard HVAC units are installed where the coil needs to be heavier duty to withstand the special application.

Adverse temperature and pressure require the use of a coil where one or both these conditions is at and/or near the maximum for the construction. In this case, the coil should have heavier tube walls and return bends and heavier fins. Sometimes the coil may need to be a different tube and fin material all together. Examples would be high temperature-high pressure hot water or very high steam pressures.

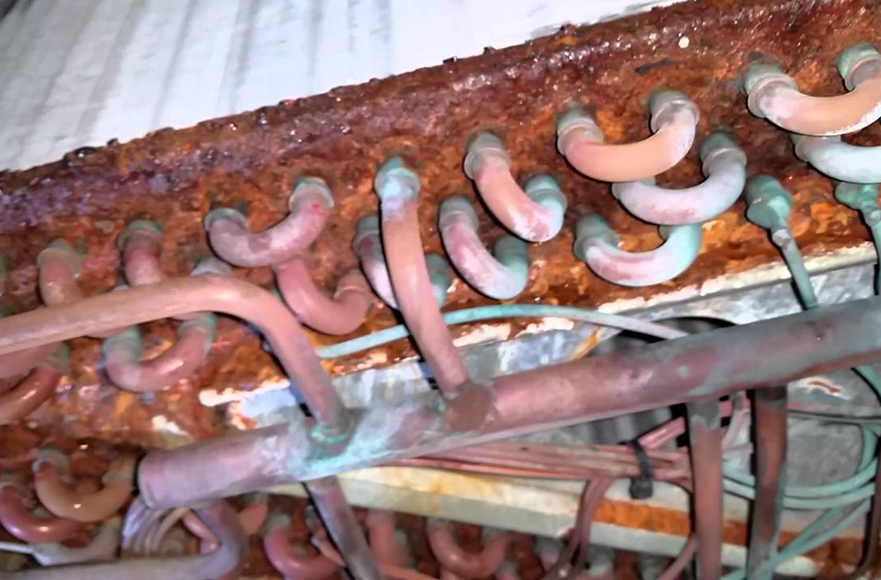

Corrosion of a coil can happen due to inadequate servicing of a coil. There are also instances where airborne corrosion can destroy a coil (i.e., salt laden air), but rarely does “conditioned air” contain a contaminant. Most corrosive problems are in water or steam. These are probably all treated; and over time, they can build corrosive agents that will destroy copper tubing. We’ve seen thousands of steam heating systems that had coils leak free for years and suddenly have massive leaks in the following 3 years. This occurs when the corrosive agent builds over time and finally has a part per thousand that destroys the coil tubes and headers.

Inadequate maintenance

Personally, I have seen hundreds and hundreds of units that have no filters upstream of a coil or have filters that haven’t been changed for 3+ years. This will ultimately cause cooling coils downstream to be plugged causing a lack of air flow, water carryover, and drastically reduced performance. There are many factors to consider with the plugging of coils and the maintenance required to keep the surfaces clear. If your coil has 12 or 14 fins per inch, you may need to clean it more often. If you have furnace filters and a dirty atmosphere, the cleaning of the surface may need to be increased to every year. Sometimes the unit doesn’t have complete access to the coils and that becomes another problem.

Condenser coils are a totally separate problem. These are the only coils mounted in a HVAC application that have no filter on its entering air side. Many times, they are 20 to 22 fins per inch and need to perform in conjunction with propeller type fans that reduce their air capacity with even the slightest increase in static pressure. Additionally, they are sitting on an open roof and are susceptible to corroding from any nearby corrosive agent. These coils need constant monitoring and must kept clean, or the CFM flow will be reduced. The resultant system performance can be reduced, and you will eventually have compressor failures.

Southwest Coil exclusively represents USA Coil & Air in the Southwestern Region and has been replacing coils for 4+ decades. With our vast knowledge and experience and a little help from our customers, we can assist you with a coil replacement that will have better performance and expanded longevity. Remember: There’s always a reason why a coil fails prematurely. We’re the coil replacement experts – Take advantage of us!

Sports quotes to tickle your funny bone:

A reporter asked a rich ballplayer how he would spend his money. “I’ll spend 90% on good times, women and whiskey. The other 10% I’ll probably waste.”

Notre Dame coach asked why his team lost today’s game. “I won’t know until my barber tells me on Monday”.

Famous hockey player on his divorce. “My wife made me a millionaire. I used to have five million”.