Why Add Construction Extras to a Replacement Coil Quote?

There are many commercial and industrial applications that have different coil arrangements and construction. Two parts of these applications remain constant. 1) Older coils will have heavier construction materials, and 2) Most HVAC coils were not constructed for all types of applications.

Keen competition over the years has increased the need for energy efficiency. Most HVAC unitary parts are now lighter duty than ever before. This includes HVAC coils. Let’s look at a typical large HVAC coil from 1970 versus the average one in 2019.

1970 – 5/8” OD x .035” wall copper tubes, .0080” thick aluminum fins, .049 wall return bends, and 14-gauge galvanized steel casings and tube sheets

2019 – ½” OD x .016” wall copper tubes, .0055 thick aluminum fins, .025 wall return bends and 16-gauge galvanized steel casing and tube sheets

Why the big difference? 1)Material costs, 2) planned obsolescence, and 3) lighter weights that were needed to lower overall unit weight and reduce freight and crate costs. If we look at unitary commercial coils (5 to 30 tons); Dx coils, hot water coils, and condenser coils have construction that’s at best marginal for many applications and will need to be replaced within the first decade of use. That’s “planned obsolescence”.

Southwest Coil wants to provide our customers with heavier duty construction (as compared to today’s normal construction) and point out the adverse applications that caused the rapid deterioration of the light duty coil that’s being replaced. The following are some of the adverse applications.

Heavier tube wall

Heavier tube walls and heavier return bends increase the coils ability to deal with expansion and contraction (all coils expand and contract based on cold and hot sides to the heat exchanger) and should be used when pressures are above 100 psi. When you select heavier materials for the tube walls, you get an extra benefit – a stronger brazed joint.

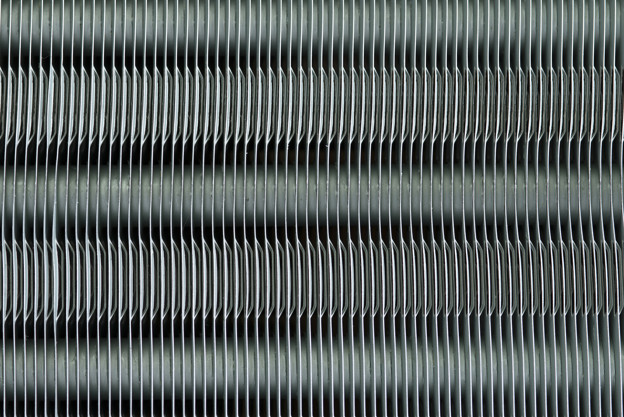

Heavier fin surface

A thicker fin gives you a slight increase in heat exchange, but it allows you to handle and clean a coil without destroying the integrity of the surface. Many 6 and 8 row coils need to be cleaned, and today’s light duty fin surfaces cannot withstand the high-pressure water and solution needed for cleaning. You can go from a dirty coil to a clean one, but you’ll have matted down fins and much higher air resistance. This is especially true with condenser coils, because they are the only coils mounted without a filter and will need to be cleaned as they are often outdoors in bad environments.

Heavier duty coil casing

Most of our casings are 16-gauge galvanized steel, but large coils might need to be 14 gauge because of the weight and handling aspects. On very large coils, we’ve even built 12-gauge casings and tube sheets.

If you have a lot of dehumidifying in a system and/or a slight amount of corrosion, then 304 stainless steel could be a great alternative to galvanized steel. We also have 16- and 14-gauge casings available.

Coatings

Today’s coatings are much better than they were even 15 years ago. We recommend coatings on coils in any type of environment that has corrosion. We will only use coatings that are baked, dipped, and electrically charged to guarantee a lifetime bond between the coating, fins and tubes. Please do not use spray on coatings. They might cover 80% to 90% of the coil, but the part that isn’t covered will cause the coil to be replaced. Simply, why have the expense if the coil protection isn’t 100%?

Ninety percent of all coils need to be replaced for a reason other than old age. Many of today’s coils have been placed in very poor designs and will need replacing within a few years. With many decades of experience, our sales professionals can pinpoint the manufacturers whose coils will likely need replacing sooner than expected, and they will only give you a 90-day guarantee on the new one. What does that tell you?

Our Sales Engineers have over 4+ decades of experience. We are the experts in this field and understand the dynamics and the process required to provide the best products and solutions for your requirements. We pinpoint the problems and provide you with professional quotes, with additions that are backed up with good reasons. Sometimes the additions are selected and sometimes they aren’t, but that’s not the point. Do you want to deal with a company that is just going to replace a problem with another problem or work with a known problem and solve it?