There are Multiple HVAC Alternatives

There are many viable alternatives for HVAC equipment that are never discussed with the end users. This is especially true with coils, fan coil units, and air handling units. We often receive questions about this equipment – especially from maintenance personnel. When we bring up these great alternatives, they say no one has ever told them about their choices. The following are two HVAC user problems that are constantly being asked of us followed by explanations and potential solutions.

Question: We have many air handlers that are not cooling as well as others and never have. We clean all of them the same and change filters at the same intervals, so there must be something different about these systems. Do you know why?

Answer: With this question, we would first look at a water side issue that may be different from the other air handling units. It probably isn’t the air side, because each unit would need to be out of air balance, while water all comes from the same source.

After a review, we will likely find that the water quantity (GPM) or the water temperature is not per the original specification. It can also be both. Here’s why. Water distribution is like a railroad, and the air handler coils are stops at each station until you get to the end of the line. Many times, units at the far end of the system (last stops) are deprived of water volume and temperature. It could be because the chiller isn’t producing enough GPM. Units closer to the chiller are taking more GPM than they should, or the pumps are undersized and can’t overcome the head pressure to these outlying units. Temperature can also be a problem due to insulation problems. In the end, there’s a distinct difference in coil performance.

Solution: Example – you are supplying 90 GPM and 48 degrees water to a coil that was sized at 100 GPM and 45 degrees water. These coils can be replaced and can be sized and circuited to overcome the water deprivation problems. If a system requires 54 degrees leaving air, and you can only achieve 57 degrees, the new coil can achieve that desired temperature through a more efficient coil. Sometimes the new coil may have a slightly higher air side pressure drop, but a simple pulley change on the supply fan can easily overcome this issue.

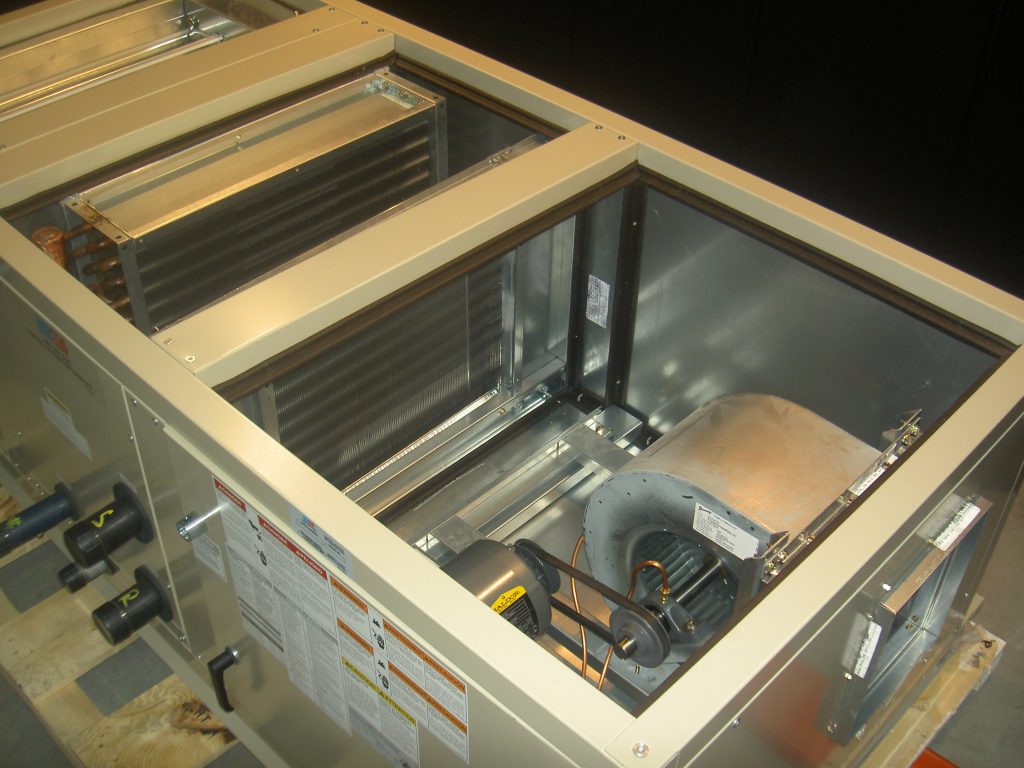

Question: Our facility has a great number of central station air handlers, and they’ve been well maintained. However, the cooling coil area is very corroded and rusted, and most of the coils are plugged. We’re thinking about having an installer replace the coils, drain pans, and reinsulate this section. Is there a better alternative?

Answer: Here’s a better alternative – replace the entire coil section versus refurbishing it. Coil sections take the brunt of dehumidified water splashing everywhere. Most older units have galvanized steel drain pans and supports and single wall insulation that’s still in the air steam. In some applications, the single wall insulation is unacceptable based on current codes.

Solution: It’s usually easy to tear up an old coil section and remove it, but a new one must be able to fit within the designated area (length, width and height) with room to move it into position. Some mechanical rooms were never designed for unitary replacement. Southwest Coil builds coil sections that can be totally disassembled and reassembled if required. Here are some of the benefits of a new coil section versus the old one:

- Coils can be designed to be more efficient than old ones and more cleanable.

- Drain pans, coil casing, and supports can be fabricated of 304 stainless steel.

- 2” double wall insulation – and where there is an inner wall – it can be fabricated with stainless steel.

- Better access, and if there is room, full size access doors can take the place of removable panels.

Southwest Coil exclusively represents USA Coil & Air in the Southwest Region. We have been involved in the replacement and retrofit of air handlers and coils for 4+ decades. From years of experience and gathering important information, we’ve found that familiarizing customers with viable alternatives can assist them in choosing an alternative that will significantly improve the outcome of a retrofit. The right alternative means problems can be solved, maintenance and cleaning improved, and more efficient performance can be achieved. Take advantage of our decades of knowledge and experience by calling or emailing us your application issues.

Famous quotes:

“Competition breeds distrust while cooperation builds trust. Sometimes it’s a long road to maximize competitiveness and cooperation.”

“All through life, you will find the same law – first the need, then the means.”

“Events are influenced by great desires.”