Room Fan Coil Units: Questions – Questions – Questions

Fan Coil units are one of the least expensive ways to heat or cool a space. The design process usually requires many questions about the unit design and its accessories, and the questions that need to be answered are not always obvious. Getting answers to the hidden questions can turn a mediocre design into a great design. The following are some of the key questions:

Where do I want to install the unit in the space?

First, you’ll need to know if you have ceiling space or closet space which provides the necessary information to choose the correct arrangement – horizontal arrangement for ceiling, vertical arrangement for closet, or furred into wall installation. Sometimes, there isn’t room above a ceiling or within an enclosure or wall, and you’ll need an exposed model.

Will the space require supply air/or return air ductwork?

This question is very important, because any unit design provides less air flow (CFM) with ductwork attached to either supply or return ends or both. Most manufacturers offer “hi static” models with increased fan sizes and/or larger motors. Sometimes these models can be physically larger, especially in depth, than their slimmer models. The rule of thumb is that slimmer models might be selected up to .2” external static pressure. After that, a hi static model or arrangement will be needed out to a maximum of .5” external static pressure. Anything above .5” will most likely require a larger belt driven unit.

Do I want the filter in the unit or in the incoming ductwork?

Normal filters for most fan coil units are 1” type and are located very close to the return air opening in a unit. If you have a fan coil unit arrangement where the return is not easily accessible, then locating the filter at the inlet grille in the space is preferred. Many installations require the occupant or service people to change these out over time, so simplicity is almost always preferred.

Two-coil or one-coil design when there is heating and cooling?

This is sometimes known as a two-pipe or four-pipe arrangement. One coil would require a changeover from heating to cooling or cooling to heating. This can be done with automatic or manual changeovers on a designated date. Four pipe means the unit has one coil for cooling and one coil for heating. There is no need for a changeover requirement. This is a major decision by the designer – whether they want to run only one supply and return for a 2-pipe system or run two supply and two returns for a 4-pipe system. Normally, it’s a decision based on “first cost” and/or the ability to deal with less control of a 2-pipe system.

Cooling and heating unitary coil selection alternatives?

Most fan coil units have multiple row selections for each unit. These can be 3 or 4 row selections for cooling coils and 1 or 2 row selections for heating if it’s a 4-pipe system. Sometimes a unit can only fit a maximum of 4 or 5 rows and is dependent on the make and model. This means the combinations might be a 3 row for cooling and 1 row for heating in a max 4-row unit or 3 row and 2 rows on a max 5-row unit or even 4 rows for cooling and only 1 row for heating. We always suggest that cooling coils be 4 rows, because the 4-row coil dehumidifies better than the 3-row coil. It may not be possible on a max 4-row design or may pigeonhole you into only 1 row on a 5-row max design. It’s best to leave these selections to the fan coil unit manufacturer, as it will have huge ramifications on the comfort aspect during the life of the unit.

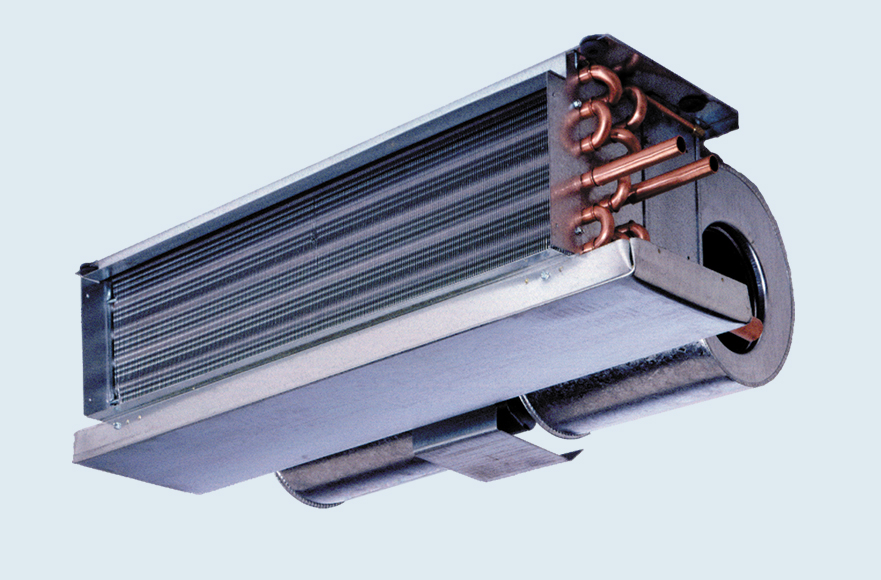

Basic or cabinet style units?

The term “basic” in fan coil units means that the unit does not have a cabinet and does not have insulation. Many fan coil unit installations have different sound requirements. It’s always better to pick a cabinet style unit that is insulated, because it’s less noisy. If a cabinet unit is chosen, it will increase the initial cost of the unit, but the benefits are significant.

Here are some other required questions in today’s fan coil market:

- Unit capacity at high or medium speed? Medium speed gives you a service factor for more air delivery if needed.

- Standard PSC motors or ECM energy efficient motors? ECM can have a financial payback in a few years but will dramatically increase your initial cost.

- Unit or wall mounted thermostats along with sophistication of the device? Many wall mounted thermostat locations are in the wrong position and are too close to either the supply or return air throw. This can reduce comfort, because the unit cycles on and off too often.

- Two-way or three-way valve packages (your choice requires either line voltage control or 24V control)? These packages usually save on the overall initial cost and can come with stop and balancing valves, circuit setters, and even strainers and other ports. These are required decisions for controlling the fluid side of the system.

- Do you want swage (brazed) fittings or unions allowing for valve package removal?

- Service switches or true disconnect switches?

- Painted or non-painted galvanized steel cabinets?

- Standard inlet and outlet grilles or upgraded grille construction (especially if the grille is exposed)?

There are many additional questions; however, these are the ones that are most needed on fan coil unit projects. Your Southwest Coil Sales Engineer can help you with all of them.

Southwest Coil exclusively represents USA Coil & Air in the Southwest Region and has been in the new project and replacement fan coil unit markets for 4+ decades. Our combined knowledge and experience can assist you with your initial design or improve unsatisfactory existing designs. A fan coil unit’s average life is 20+ years, so it’s important to look at all design facets before making decisions that may prove costly during the life expectancy of these systems.

For inquiries, please contact:

Tom Jacobs

610.580.3004 or [email protected]