Coil Selections Made Easy

You think making coil selections are complicated now? As a young Sales Engineer in the 70’s, I used a slide rule to select coils. It took me 15 minutes to select just one chilled water coil 4 decades ago versus about a minute today. When I bought my first Texas Instrument Calculator, it assisted me in quadrupling my output. That was real progress. Yet today, we have computer software to increase the speed, accuracy, and array of coils we can select for our quotations. Who knows what we will have in the near and far future to make our jobs even more productive.

At the same time, it’s still very important to understand which coil to select and why that selection was made. The speed of coil selection has changed significantly, but what hasn’t changed is the requirement that specific, quality information be input into the computer to obtain the best coil selection for your physical parameters and arrangement.

INPUT REQUIREMENTS

Heating coils require 1) air flow volume, 2) altitude, 3) entering air temperature, 4) entering water temperature (or steam PSIG if steam heating) and 5) capacity requirement, which can be in BTUH or can be stated in desired leaving air temperature. If water heating, provide a desired leaving water temperature or volume of water normally stated in GPM.

If cooling, you must add wet bulb temperatures to entering and leaving air temperatures. If the coil is a wet coil (meaning it will dehumidify), the coil selection must meet both the sensible heat and total heat calculation. NOTE: The total heat is nothing more than the sensible and latent heat added together.

If cooling with refrigerant, you must specify the refrigerant type and the correct suction temperature to meet the BTUH requirement. This suction temperature can be found by looking at the high-pressure side to the refrigerant (compressor/condenser). This side will meet the required BTUH load at a specific suction temperature. It’s this suction temperature that is used for the coil selection to make sure they match.

All coils require a designated size be provided and a required arrangement. Heating coils or cooling coils that are dry cooling do not need to be below 550 feet per minute velocity. However, cooling that is dehumidifying must have velocity across the coil at less than 550 FPM because of a systematic problem called “water carryover”. When the speed of air is over 550 FPM, you may start to pull water off the face of the coil and downstream into fans and supply ductwork. Normally, coils are rectangular, with the height about one half of the length.EXAMPLE: 30” high x 60” long. When inputting your selections, you will need to specify if the coil connections need to be on the same end of the coil or can be at opposite ends.

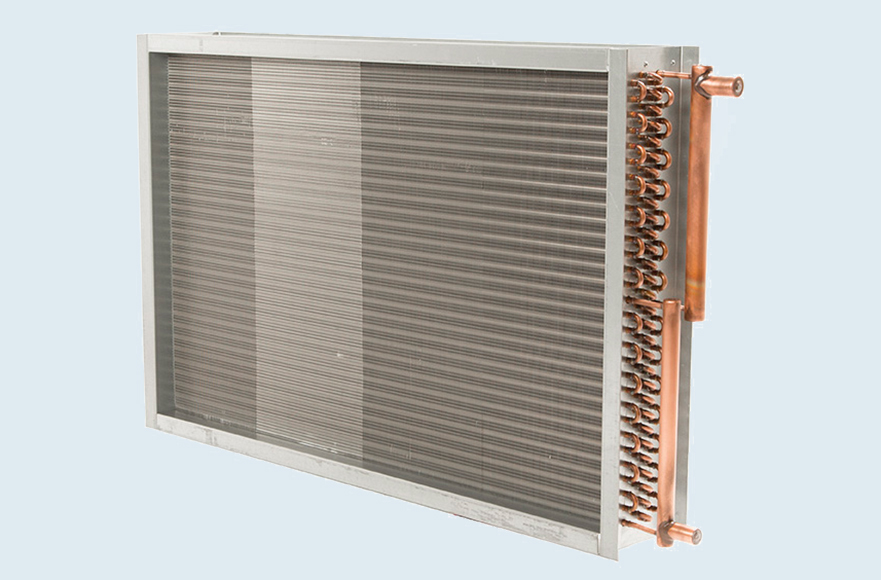

It’s necessary for you to provide specifics for the construction of the coil, which include 1) tube diameter, 2) tube thickness, 3) fin material, and 4) thickness. Alternative materials may increase or decrease heat transfer. If you want to clean a dense coil based on the requirement in a atmosphere, you might specify flat fins, which are more cleanable than corrugated and rippled fins. You might also want to maximize the number of fins per inch for cleaning ability as well.

Lastly is pressure drop requirements. Fans and pumps all deliver flow against resistance. The coil selection must have parameters for maximum air pressure drop (inches of water) or water pressure drop (normally in feet of water).

SELECTION

A computer coil selection program is internally selecting many different alternatives with your input. In the end, it normally will give you the one that will meet all your criteria. This selection will always be just a tad more than your requirement, because the computer is finding a coil with rows, fins per inch, and circuitry that meets your criteria.

As the selector, you can look at this base line selection and come up with alternative selections that may be just short of requirements but may be more beneficial in the long run. I have seen instances where two tenths of a degree can change a coil from a 6-row selection to an 8-row selection. As an example, can the end user live with 54.2 leaving air versus 54.0, which would give them the benefit of a 6-row coil versus an 8-row coil? The benefits are lower cost, lower air resistance, probably less water side pressure drop, and easier to clean.

Review the attached coil selection, and you can see all the required data and what has been selected. Never underestimate the abilities of a coil engineer that selects coils all day every working day. As easy as these coil selections can be, the fine tuning requires years of experience and working knowledge. Take advantage of our decades of expertise in the coil replacement business – that’s what we’re here for!