Are Coils the Culprit Behind Decreased A/C Unit Cooling?

Almost all packaged A/C or split system units do not have a service factor for extra capacity. Even when new, these units may not yield the cooling BTUH capacity specified due to improper installation and/or incorrect load calculations at the inception of installation and startup. Consequently, as the system gets older and parts become less efficient, the system may lower its capacity to the point where it’s no longer adequately cooling. Many times, heat exchanger coils are a large part of the problem.

There are two types of coils in an A/C unit. The 1st is the air-cooled coils. They are the evaporator coils which cool the room’s air flow and ultimately supply the cooling BTUH to meet the needed load condition. The 2nd is the condenser coils. These coils remove heat from the refrigeration process. There are also two calculations of heat – 1) the heat that refrigerant received at the evaporator, and 2) the heat of compression. These two heats combined are known as “total heat of rejection”.

The following discusses both types of coils and their potential problems:

Evaporator Coils

Many units fabricated over the last decade have used enhanced tubing and fin surfaces to achieve maximum heat transfer to reduce motor horsepower and increase efficiency ratings of the entire unit. It’s important to understand that any coil increases its BTUH capacity when the air is in touch with the surface. You will get more BTUH per square foot of surface when air contacts with the primary surface (tubes) and with the secondary surface (fins). That’s a positive. The negative aspect is that the very tight heat transfer surface can also become dirt laden and cause a tremendous reduction in heat transfer.

When a coil becomes dirt laden, it reduces heat transfer in two ways. The 1st is a reduction in air flow which is required to meet the BTUH criteria. More air resistance equals less air. You may be able to increase the supply fan RPM, but most times the BHP (brake horsepower) is now beyond the motor horsepower capacity and a whole new motor and drive may be needed. The 2nd reason is that dirt and foreign material acts as an insulator. The heat transfer from the colder refrigerant inside the tube and the warmer air on the outside now has an extra barrier between them that will reduce capacity.

Most new A/C units have furnace filters or at best MERV. 8 filters. Filters MUST be changed out in a timeframe that never allows the evaporator coil to load up with foreign material. There is a simple air test that can be done that will tell you if an evaporator coil is loading. (This can also be used for condenser coils.) Measure the air velocity on the leaving air side of the coil and take 4 to 6 readings over the entire face of the coil. These readings should be within 10% of each other. If any of the velocities in feet per minute are significantly below or above 10%, you will know the coil has foreign material inside.

Condenser Coils

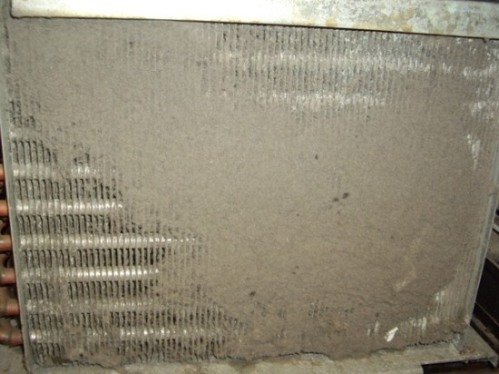

Air cooled condenser coils are the only HVAC coils installed that don’t have an air filter on its entering air side. In addition, almost all condenser coils have a very tight and packed fin surface. Today, many units are 18 to 22 fins per inch. Going back 30 years, this number of fins per inch was unheard of. Why? Maximum heat transfer and the smaller the coil means less weight for the unit. We’ll even add a 3rd problem with condenser coils that’s created when the condenser fans are selected without a margin to supply needed air flow across the coil surface.

If you consider the three characteristics above, then any foreign material inside these coils will affect the capacity of the condenser side of the system. All installations are not the same. Some installations are in clean atmospheres while others may be in environments that have very dirty and corrosive outside air (such as industrial areas, airports, and coastal areas). Due to their construction, condenser coils are natural dirt collectors.

When loaded, the same heat transfer reduction occurs the same way as in the evaporator coils. The air flow is reduced and the insulation factor between the refrigerant inside the tubes and the air on the outside of the fins further reduces the heat transfer. However, the air flow reduction is more pronounced with a condenser coil, because propeller type fans really reduce CFM flow with extra resistance, much more so than a unit’s supply fan. We’ve seen air flow and capacity so reduced that over time it’s caused compressor failures.

The owner must clean these coils as determined by the environment surrounding the unit(s), which may mean an accelerated cleaning schedule. Any coil that has corrosive agents attacking its surface (industrial byproducts or salt laden atmosphere) should have a baked and dipped coating to protect them. When cleaning any condenser coil, be certain to rinse and re-rinse the cleaning agent to ensure it’s not sitting on the surface. We have seen many condenser coils that have had to be replaced because the cleaning agent clogged up the coil.

Southwest Coil represents USA Coil & Air exclusively in the Southwest Region. We have replaced tens of thousands of evaporator and condenser coils over 4+ decades. We know there are times that an alternative selection or construction may be required to help achieve maximum efficiency. We have the best coatings in the industry, unsurpassed crating, and expedited lead times that are unmatched by our competition. We invite you to take advantage of our years of knowledge and experience to create better solutions.